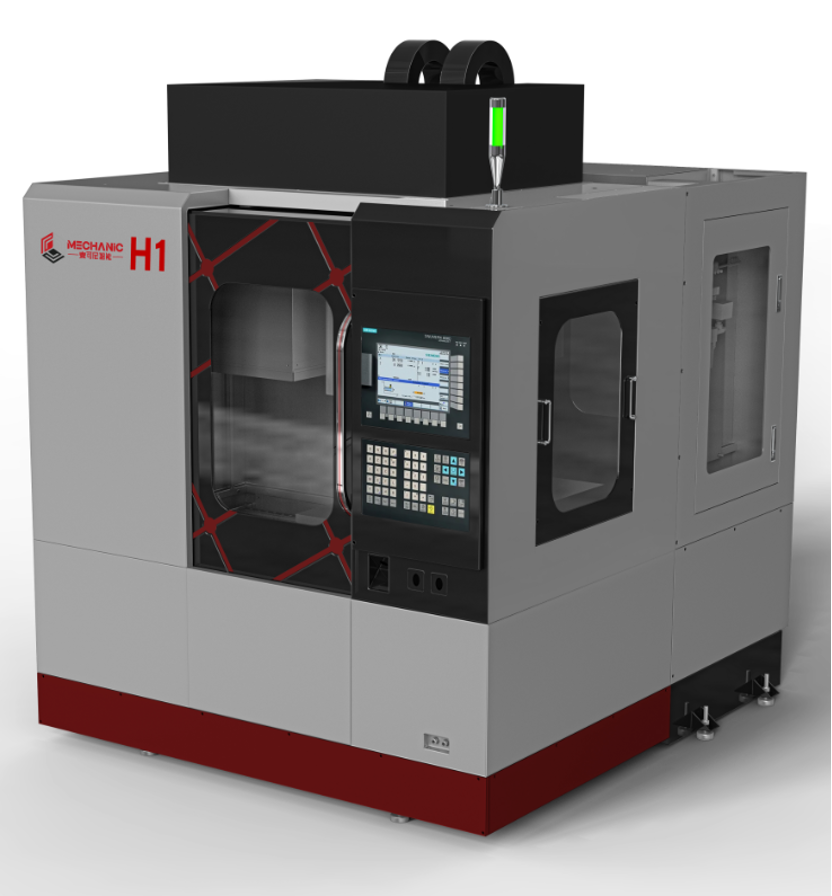

CNC Vertical Machining Center (Linear motor)

MODEL H1:

High Precision Gantry StructureThe H1 is a high-speed, high-precision vertical machining center with a rigid gantry structure, ideal for the processing of precision components in 3C, medical, defense, mold, copper, and turbine industries. The frame is made of high-grade cast iron, fully annealed for excellent dimensional stability and minimal deformation. Finite Element Analysis (FEA) ensures optimal mechanical performance.

Linear Motor + Laser Feedback SystemEquipped with a SUCC linear motor configuration and three-axis laser interferometer feedback, eliminating backlash and thermal expansion issues common in screw-driven systems. The integrated SUCC control system delivers outstanding accuracy and machining efficiency.

High-Rigidity Guide RailsAll three axes use 35# SP-grade roller guide rails, offering high load capacity, excellent rigidity, and extended machine lifespan.

High-Speed Milling SpindleThe electric spindle features high-precision bearings and optimized shaft arrangement, providing exceptional accuracy, stability, rigidity, and load capacity. A built-in cooling channel paired with an external chiller allows rapid thermal balance, improving product dimensional stability and spindle longevity.

Integrated Grease Lubrication SystemStandard grease-based system provides thorough lubrication of all moving parts, ensuring smooth operation, longer service life, and a cleaner internal environment compared to conventional oil lubrication.

Double-Layer Axis ProtectionThe X and Y axes feature dual-layer protection: an internal accordion-style organ shield and an external telescopic steel cover, protecting the linear motors and optical encoders, and extending their service life. The Z-axis includes high-quality covers and an SMC counterbalance cylinder to prevent spindle drop in case of power failure.

Enhanced Cooling SystemTwo high-power coolant pumps ensure complete cooling of tools and workpieces during machining, with effective flushing and chip removal.

Constant-Temperature ChillerA precision water chiller cools both the spindle and machine base simultaneously with ±0.1°C accuracy, maintaining thermal stability and machining precision.

Ready for immediate delivery

Engineered for Demanding Applications

- We provide full professional installation and comprehensive operator training to ensure smooth deployment and operation.

- Maintenance and support services

- The product complies with all required certifications for operation within the EU.

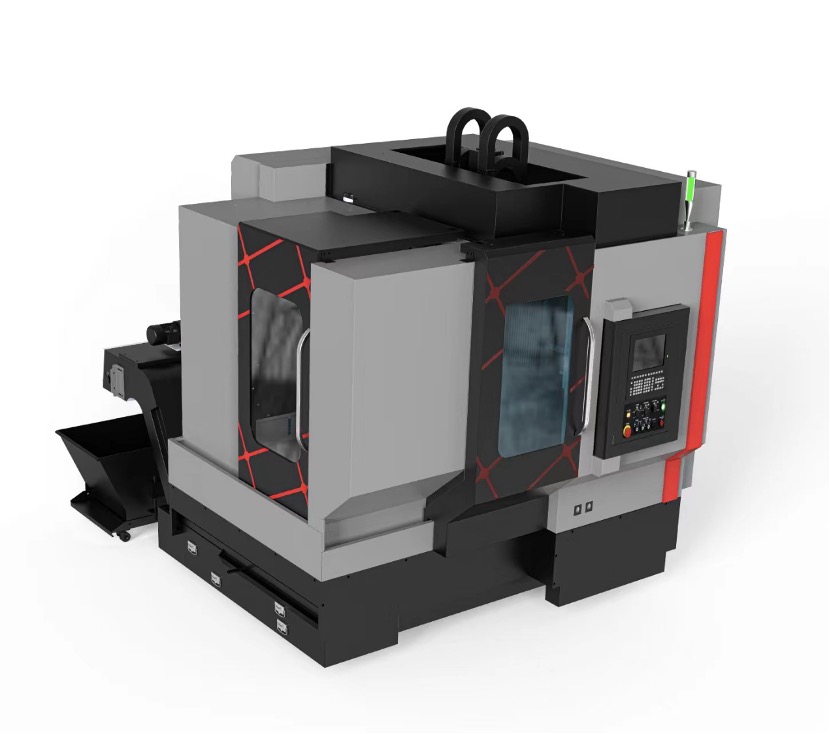

CNC Vertical Machining Center (Linear motor)

MODEL H1:

MODEL H2:

Key Advantages Over H1

5-Axis Linkage Machining H2 supports full 5-axis simultaneous machining and 4-axis multi-surface machining in a single setup, which H1 does not.→ Enables greater flexibility and efficiency for complex parts.

Dual Linear Motor Drive Compared to the single linear motor drive in H1, H2 offers higher power and better axis synchronization. Improved motion control and speed.

Optional 30.000 rpm High-Speed Spindle H2 offers up to 30.000 rpm, while H1 is limited to 24.000 rpm. Better for fine machining and high-precision surface finishing.

Oil-Air Spindle Lubrication Provides superior cooling and cleanliness over H1’s standard water-cooled system. Longer spindle life and better thermal stability at high speeds.

Automatic Tool Measurement System H2 includes an auto tool setting and coordinate system calibration feature, saving setup time and increasing accuracy. Not available on H1.

Stainless Steel-Covered Axis Guards Enhanced chip protection with stainless steel-reinforced bellows, reducing wear from metal chips. More durable than H1’s standard protective design.

Improved Chip Disposal and Cleaning Access Sloped worktable and rear-side chip discharge provide easier cleaning and maintenance. More user-friendly than H1’s basic layout.

Ready for immediate delivery

Engineered for Demanding Applications

- We provide full professional installation and comprehensive operator training to ensure smooth deployment and operation.

- Maintenance and support services

- The product complies with all required certifications for operation within the EU.